TechnoStar Shipbuilding Seminar 2014 Report

Thank you very much for visiting the “TechnoStar Shipbuilding Seminar 2014”.

More than 100 customers (excluding internal and related parties) visited us, and we were able to successfully complete eight lectures and panel discussions.

We would like to express our sincere gratitude to all of you for your supports.

We will continue to listen to your opinions and strive to improve not only shipbuilding technology but also CAE technology, so we ask for your continued guidance and encouragement.

In conclusion, I wish you all the best and best of luck, and I would like to express my gratitude.

For your reference, please see the program of Shipbuilding Seminar 2014 and the application form for handouts of presentations as below.

TechnoStar Shipbuilding Seminar 2014 Program(PDF)

Shipbuilding Seminar 2014 Seminar Material Download Application Form

(new window will open and go to the application form screen)

TechnoStar Co. Ltd.

Representative Director

Seminar day

Greetings from TechnoStar Shipbuilding Seminar 2014

■TechnoStar / Mr. Masaru Tateishi

President Tateishi talks about TechnoStar’s history and future,

and passion for the shipbuilding industry

Lecture

■Japan Marine United Co., Ltd./ Mr. Hiroaki Ogawa

「Development of buckling / final strength analysis support tool for flexible panel」

Lecture summary

The buckling / final strength evaluation of the hull structure is very important in the ship design, and one of the evaluation methods is the FEM analysis method of the flexible panel. While this method provides highly reliable results, it’s extremely complicated and requires various MPC settings and initial deflection input. Therefore, we have developed a tool on TSV-Pre that can consistently and efficiently perform everything from model creation to analysis condition input. With this tool, the evaluation time has been dramatically reduced, and buckling and final strength evaluation can be performed in various cases.

Mr. Ogawa is listening to the questions from the audiences

Mr. Ogawa is listening to the questions from the audiences

■Hiroshima University / Ass. Prof. Satoyuki Tanaka

「Simulation of surface crack growth in a cylindrical joint」

Lecture summary

The simulation results of the growth of surface cracks generated at the weld toe of a cylindrical joint are reported. Using the fracture mechanics analysis function of TSV-Pre, the fracture mechanics parameters were calculated and the cracks in the curved surface shape were modeled by the tetrahedral quadratic elements. The results of examining the effectiveness and validity of this approach by comparing it with the crack growth phenomenon obtained by the fatigue strength test are shown.

Professor Tanaka answering questions from the audiences

■Samsung Heavy Industries/Mr. Jaehan Lee

「Simulation Study using TSV-BLS(TechnoStar-Block Lifting Simulation System) for Heavy Block Lifting By Giant Facilities in SHI(Samsung Heavy Industry) 」

Lecture summary

SHI is building many different types of vessels and marine structures with shorter delivery times each year. Therefore, the complicated studies are required to strictly evaluate the safety of block lifting work using various large equipment of shipyards for these large blocks. In order to carry out the examination work efficiently and easily and create a block lifting work plan. Currently, SHI is evaluating the validity and safety of the block lifting work procedure using TSV-BLS simulation. In this presentation, we will introduce the following research cases.

・Strength evaluation and buckling strength evaluation by lifting blocks

・Confirmation of interference by lifting blocks with accessories

・Strength evaluation of the Carrier

Mr. Lee giving a lecture in English (left)

Mr. Kobayashi (right) – TechnoStar Engineering Department- is explaining the content of the lecture in Japanese.

■Oshima Shipbuilding Co., Ltd./ Mr. Yuji Miyoshi

「Development of CSR-B direct strength analysis evaluation system using parametric modeling system TCAD」

Lecture summary

We have developed a direct strength analysis evaluation system based on CSR-B as TCAD / DSA under joint development with TechnoStar. The features of this system are parametric modeling using TCAD technology and a one-stop evaluation system that allows the automatic works from modelling to report output based on the EXCEL input data. In this lecture, we will explain the contents of the development system and report some application examples using this new tool.

Mr. Miyoshi listening to the questions from the audiences

■Japan Marine United Co., Ltd./ Mr. Tetsuya Tokumoto

「Structural analysis post processing software「Ship Post」Introduction」

Lecture summary

Until now, the “primary evaluation system” developed in-house about 20 years ago has been used for many years for structural analysis post-processing. However, because the software was old, I was dissatisfied with its usability and processing time. Therefore, the primary evaluation system has been renewed, and new software that incorporates efficiency and functional improvements in addition to the conventional functions.「Ship Post」was developed using TSV-Post as a platform. This time, we will introduce the background, functions, and prospects for future functional improvements that led to the development of 「Ship Post」.

Mr. Tokumoto talking about future functional improvements

■Tokai University / Professor Hideyuki

「Development of inboard noise prediction method and prediction program」

Lecture summary

The IMO inboard noise code has been amended to regulate inboard noise levels for vessels contracted after July 1, 2014. In order to satisfy the noise level regulation value, it is necessary to predict the noise level at the design stage and take appropriate measures without fail. In order to accurately predict the noise level, it is indispensable to construct an appropriate noise propagation model and prepare reliable vibration / acoustic characteristic data. We will introduce the development of a practical noise prediction program that combines the Janssen method and the SEA method.

Mr. Yoo – TechnoStar Engineering Department – demonstrating the inboard noise prediction program

■National Maritime Research Institute / Mr. Taketaka Ogawa

「Development of NMRI-DESIGN – An integrated analysis system for all ship loads and structures for advanced hull structure design」

Lecture summary

Due to the recent increase in size and new format of ships, there is a need for a wider range of strength studies than ever before. In addition, the development of computers and the formulation of the Goal-Based Standards (GBS) by the International Maritime Organization (IMO) are accelerating this trend. Against this background, the National Maritime Research Institute has developed NMRI-DESIGN – an integrated analysis system for all-ship load structures – to help examine structural design and standards based on a more rational evaluation system. In this lecture, we will introduce the outline of the system and verification examples. Furthermore, we have also developed a platform for processing these easily and at high speed in collaboration with TechnoStar Co. Ltd.

Mr. Ogawa talking about an example of fatigue strength evaluation by NMRI-DESIGN

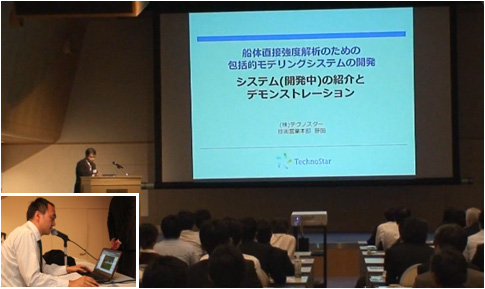

■Nippon Kaiji Kyokai / Mr. Hiroshi Ochi

「Research and development of automatic modeling system for hull direct strength analysis (Introduction on the joint research and development of ClassNK)」

Lecture summary

In order to design and develop container ships and those ships that required to apply the harmonized CSR have been becoming larger in recent years, direct strength analysis using the FE model of all ships is indispensable. On the other hand, the existing FE Modeler has not been able to realize the initial design stage and short-term modeling required by the designer, as well as the flexible response to design changes.

In ClassNK’s joint research and development efforts, we are currently developing an efficient modeling system that supports the above, so we will introduce the concept.

Mr. Ochi explaining the items of the lecture contents

Mr. Fujita – General Manager of TechnoStar Engineering Department – demonstrating the system under development

Panel Discussion

■Theme: The role of CAD / CAE in the shipbuilding industry

「The role of CAD / CAE in the shipbuilding industry」Each presenter discussing their own opinion on the theme